A Snapshot of State Appliance Standards in 2025

At 2050 Partners, we understand that codes and standards are among the most cost-effective tools for reducing greenhouse gas emissions, lowering energy bills, and bolstering grid resilience. Although federal appliance standards now cover many types of products and equipment, states still have a large role to play in pushing appliance efficiency forward. In a prior blog post, we explored the history of state appliance standards in California and throughout the United States. In this second installment of our three-part series, we summarize current state standards, identify the key components of a standard, and discuss opportunities for states to become more involved. Finally, in a future article, we will provide a roadmap for states looking to create new appliance standards programs or expand upon existing ones in this time of uncertainty and rollbacks at the federal level.

Where We Are Today

As we briefly discussed in the first article of this series, the Department of Energy’s federal appliance standards program has expanded significantly over time. Today, DOE’s test procedures and appliance standards cover over 60 categories of appliances and equipment and have delivered substantial energy savings nationwide. According to DOE, standards implemented since 1987 have reduced utility bills for American households and businesses by $105 billion in 2024 alone.

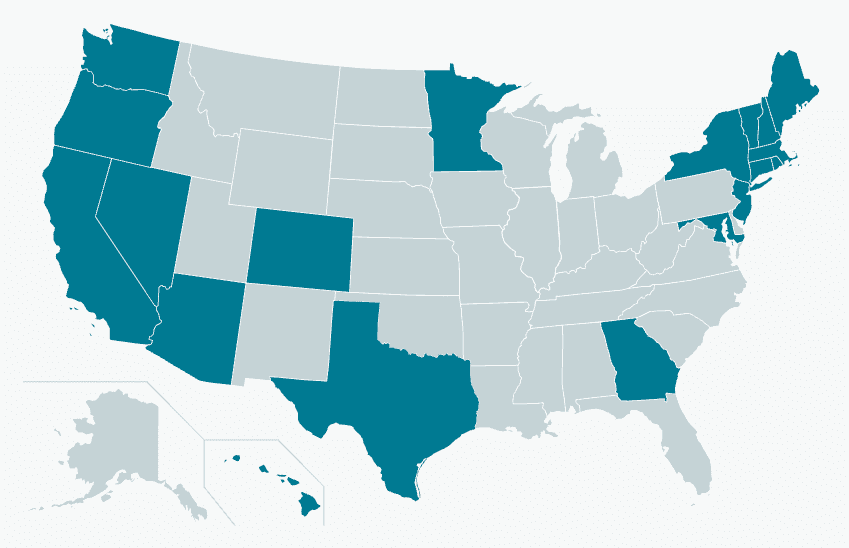

While each expansion of federal appliance standards has led to additional preemption considerations, states have still been finding ways to push appliance efficiency forward. States have historically led in the development of standards for products without federal standards, often driving DOE to meet or exceed those standards after state standards lead to energy efficiency improvements across the market. According to the Appliance Standards Awareness Project (ASAP), 18 states plus DC have adopted their own appliance standards to target products not covered by federal regulations. For example, Massachusetts regulates the sale and installation of electric vehicle chargers, and California has established standards for computers.

For a full list of state standards, refer to the American Council for an Energy-Efficient Economy’s (ACEEE’s) Appliance Standards Summary or Climate XChange’s State Climate Policy Dashboard.

States with enacted appliance standards, as of September 2025. Image Source: Climate Policy Dashboard

While there are many states that have enacted appliance standards, how states choose to pursue these standards can vary significantly. At the highest level, states can choose to set standards through legislation or regulation. While both pathways aim to improve energy efficiency and reduce emissions, the selected path has significant implications for flexibility, speed, and long-term enforceability. In the following sections, we will detail each of these options and identify states that have taken each path.

Legislative Standards: Certainty Through Statute

Legislative standards are created directly through state law. Although each state has its own legislative process, statutory standards typically begin with legislators drafting a bill, often in collaboration with energy offices, environmental advocates, or utility stakeholders, and end with a governor’s signature. The bill will typically specify what appliances are covered, their performance thresholds, and enforcement timelines. Some bills delegate limited authority to state agencies to define technical details or update standards administratively, but the core framework is embedded in statute.

Pros of Legislative Standards:

- Durability: Because these standards are written into law, they are harder to overturn and provide a strong signal to the market.

- Clarity: Legislated standards offer clear and specific direction for manufacturers, retailers, and enforcement agencies.

- Political legitimacy: Having gone through a public legislative process, these standards often carry more political weight.

- Speed: Legislative calendars follow a rigid timeline, with legislation typically enacted within a year and no later than two years after the bill is introduced. Barring opposition, the legislative process is usually faster than a regulatory process.

Cons of Legislative Standards:

- Inflexibility: Updating standards requires going back through the legislature, which can be slow and politically challenging.

- Partisanship: The legislative process can stall if there is divided government or industry opposition.

Washington, Oregon, and Colorado have all set appliance standards directly through legislation. For example, in 2022, Washington passed House Bill 1619, which set or updated standards for six product classes. In 2021, Oregon passed House Bill 2062, which expanded the state’s existing standards to include product classes such as commercial dishwashers and commercial fryers. Finally, with HB23-1161, Colorado set new minimum energy efficiency standards for several new product classes, such as commercial ovens, showerheads, and high-efficacy lighting.

Regulatory Standards: Agility Through Agencies

Regulatory standards, on the other hand, are established by state agencies such as an energy office, environmental department, or public utilities commission, under authority granted by statute. Before finalizing standards, agencies typically prepare a technical and economic analysis, encourage stakeholder engagement, and follow rigorous rulemaking procedures.

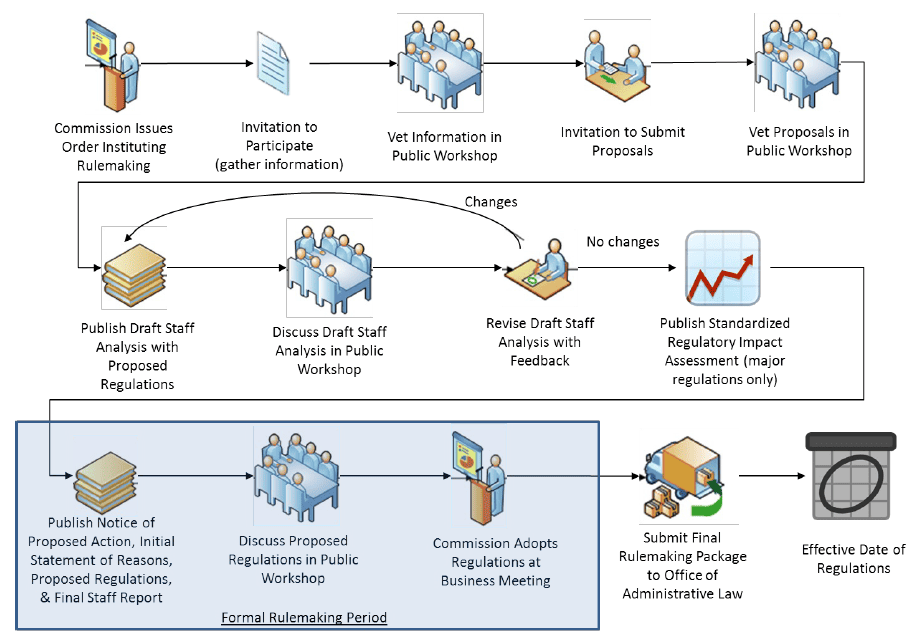

As an example, the image below provides an overview of the California Energy Commission’s (CEC’s) rulemaking process for appliance efficiency regulations. This docket database provides the record for each of CEC’s past rulemaking processes.

CEC Appliance Efficiency Rulemaking Process. Source: California Energy Commission staff

Pros of Regulatory Standards:

- Flexibility: Regulatory agencies can update or refine standards more frequently to align with technological advances, improvements in efficiency, or changes in the market.

- Technical expertise: Agencies are better equipped to perform the detailed analysis needed to maximize energy savings that are achievable and cost-effective.

- Informality: Because agencies are less formal places for public engagement than a legislative hearing, agencies can typically gather candid public input and deep stakeholder engagement on proposed standards.

Cons of Regulatory Standards:

- Political risk: Agency rules can be reversed more easily than statutes, especially when new administrations take office, creating uncertainty for manufacturers.

- Less visibility: Regulatory processes are sometimes less transparent to the public and stakeholders if not managed carefully.

For example, California, New York, and Massachusetts have delegated authority to the California Energy Commission, NYSERDA, and the Massachusetts Department of Energy Resources, respectively, to establish and update state appliance standards.

Key Components of a Standard

Despite their procedural differences, legislative and regulatory standards share several key features that help ensure the intended energy or water savings are realized.

California’s early leadership on appliance efficiency standards established the basic analytical framework for deciding whether an appliance standard is worth adopting. Each of the factors listed below is informed by stakeholders who participate in California’s rulemaking proceedings and by staff experts within the CEC who prepare staff reports analyzing each component of the standard. Many other states and the DOE have since adopted similar frameworks for justifying appliance standards.

- Technical feasibility: Technical feasibility means that products meeting the standards can be manufactured with readily available or emerging technologies. Technical feasibility can be demonstrated by a product that already meets the proposed standard, or by showing how a new technology can be incorporated into an existing product to meet the proposed standard.

- Cost-effectiveness: Cost-effectiveness typically means that the long-term utility bill savings from a more efficient product exceed the incremental purchase price of the more efficient product. Some states have considered additional factors in the cost-effectiveness analysis, such as the avoided cost to the utility from grid upgrades or procurement, the social cost of carbon, or the manufacturer production cost of the product.

- Significant energy savings: There is no minimum threshold for the estimated energy savings resulting from a standard, but each regulation must be worth state resources to pursue. Key inputs to energy savings estimates are the existing stock of the product class and its annual sales in the state. What counts as “significant” will differ for each product, based on things like its projected market share, the difference between baseline and proposed standard levels, the ease of the regulation or analysis, the technologies available to meet the standards, and the level of stakeholder engagement.

- Other economic and environmental factors: CEC also considers the impact of the standards on product efficacy, housing availability, businesses and local governments, and the environment, as well as the total statewide costs and benefits and alternatives to the proposed regulations. In some cases, CEC prepares a macroeconomic assessment of the regulation’s direct and indirect economic impacts in the state.

- Effective dates: California requires that a standard take effect no sooner than one year after it is adopted, and that it not be amended for at least five years after its adoption. These provisions give manufacturers time to modify and certify their products to comply with the standards and to have certainty for future investments. The effective date can affect the technologies available and the cost to implement a proposed standard.

The Opportunity for States

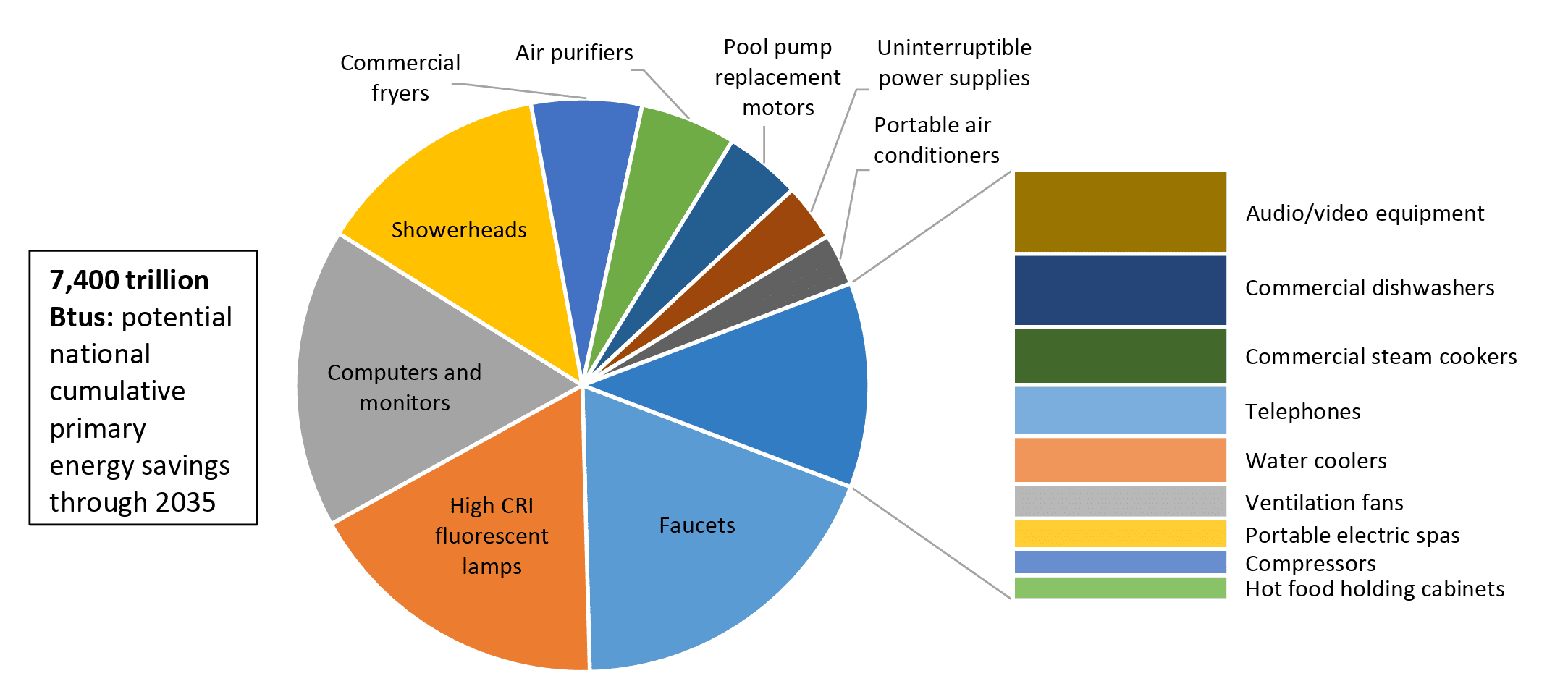

In a 2017 report about state appliance standards, ASAP and ACEEE identified 21 non-preempted product classes where states could still have an impact. If states were to implement all of the recommended standards, the authors estimated net present value savings of $113 billion (2016$) and energy savings of 590 TWh between 2020 and 2035. Potential energy savings by product class are shown in the image below.

ASAP has continued to update this analysis annually based on updates to federal and state standards, and current state-by-state savings estimates for each product class can be found in this database. This data demonstrates that there remains significant opportunity for states to drive energy and water savings through appliance standards.

Appliance Efficiency Through Building Codes

States can also improve appliance standard efficiency through their building codes even for federally regulated products, although this approach is much less direct and offers less certainty for savings. Building codes are not preempted by federal appliance law if they meet a seven-factor test established in the statute (42 U.S.C. § 6297(f)(3).) States have used building codes to improve appliance efficiency in two key ways.

In Washington, the state adopted building code changes that would allow either gas or electric products to be installed in buildings, but includes additional building system requirements to mitigate the additional energy use from gas-fired systems, adding to the cost of a building with gas combustion. In contrast, buildings with heat pump technologies avoid additional requirements and have a lower building cost, with an equivalent energy use to the gas building. This approach meets the seven-factor test for preemption and drives the adoption of electric technologies in buildings, as detailed in this recent report presented at the 2024 ACEEE Summer Study.

Another commonly used exception is sometimes called the “ASHRAE” rule. For commercial HVAC and water-heating equipment that is subject to regulation under ASHRAE 90.1, states can adopt either the minimum DOE standard or the ASHRAE 90.1 standard in their building codes. When the ASHRAE standard is more stringent than the federal minimum standard, this can lead to significant efficiency savings.

Other Opportunities for States

Even when states cannot set their own standards for products due to preemption, they can help improve federal efficiency standards by participating actively in federal proceedings, doing research or supporting data collection to inform federal standards, and advocating through their Congressmembers for improved federal efficiency standards.

We should acknowledge that the federal appliance standards law allows DOE to waive preemption for state appliance standards if the state proves its need to meet unusual and compelling state or local energy or water interests. (42 U.S.C. § 6297(d).) However, DOE has never granted such a waiver (even when a court subsequently determined it denied one waiver unlawfully). There may be a few circumstances that merit a look at the waiver approach, although waivers are even less likely to be granted in today’s political environment.

Looking Ahead

As we stated in our previous post about the history of state appliance standards in the U.S., states have the authority, the precedent, and the public support to enact and enforce standards that reduce energy use and promote sustainability. In our next and final post of this series, we will further explore the opportunities available to states today and provide a roadmap for states that want to expand existing programs or implement standards for the first time.

At 2050 Partners, we are committed to helping our clients leverage energy efficiency standards, building energy codes, and innovative policy strategies to drive decarbonization and energy equity. To learn more about our work and how we can support your organization, please contact us today.