Understanding Heat Pump Water Heater Ventilation

Overview

Since 2017, 2050 Partners has been the project manager overseeing research to better understand equipment performance and provide that data to support adoption of enhanced building codes and standards. For the purposes of this project, we focused our efforts on heat pump water heater ventilation.

Client Background

Our client is a large provider of electric and natural gas service in California. 2050 Partners has worked in close collaboration with several subcontractors, equipment vendors, and other key stakeholders during this project.

The Challenge

The current California Building Standards Code, Title 24, does not include minimum ventilation requirements for residential heat pump water heaters (HPWH). HPWHs are an all-electric water heating option that can achieve efficiencies three or more times greater than conventional electric resistance or combustion gas water heaters. To realize their highest efficiency levels, HPWHs require certain installation conditions. For example, a sufficient thermal energy resource is required, which is ensured by providing adequate ventilation. If building owners across California install HPWHs in small closets without adequate ventilation, the HPWH will likely operate too often in electric resistance backup mode, yielding poor overall equipment performance, higher utility bills, and problematic spikes in demand on the power grid.

This undesirable outcome was observed on a recent PG&E Code Readiness research project in Davis, California, where the lack of adequate ventilation led to cool exhaust air circulating in a small closet. The result was a very cold closet where the heat pump could not operate as expected, leading to excessive electric resistance backup element operation. To realize the potential of HPWHs to reduce energy use and greenhouse gas emissions, and to avoid stresses on the electric grid, contractors, homeowners, and industry stakeholders need proper heat pump water heater ventilation installation guidance.

Solution

The research team, coordinated by 2050 Partners, was interested in exploring this phenomenon further and initiated a laboratory test project in fall 2022. This project aimed to understand the impact of airflow and installation location on HPWH performance, outline HPWH installation best practices, and identify opportunities for codes and standards enhancements.

The Project Team tested three water heater products under different intake and exhaust ventilation configurations and ambient air temperature conditions to replicate typical HPWH installations in new and existing residential and multifamily buildings. This project built on previous work funded by the Northwest Energy Efficiency Alliance.

Findings

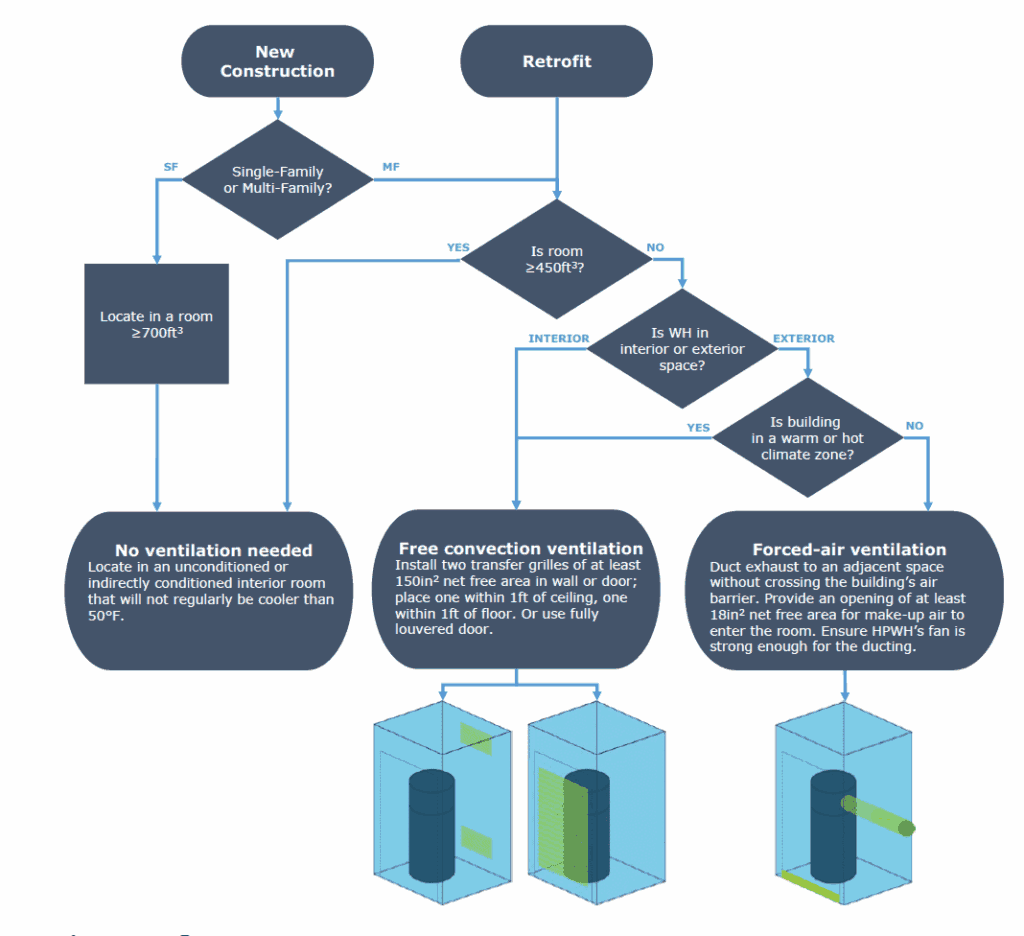

The findings included a best practices approach to the installation of HPWH as shown in the graphic below.

Additional Findings

- Evaporator fan strength plays a critical role in the effectiveness of ducting HPWH exhaust and/or intake air: stronger fans tend to increase the benefit of ducting.

- The presence of “clutter” filling the HPWH closet (e.g., boxes filled with and without paper), had a minimal impact on HPWH performance, indicating HPWHs can perform well in cluttered rooms as long as the grills are unobstructed.

- Dual-ducted installation (intake and exhaust ducted to a space other than the HPWH installation room) may be a practical option depending on the HPWH model and the temperature ranges experienced in the secondary space. The project lab tests demonstrated successful HPWH operation across 50-115 °F intake air temperatures but never found the extreme boundaries, suggesting the range is somewhat wider.

- Differences in specific component selections and design choices across HPWH products lead to different HPWH models responding better or worse to the above-described installation behaviors.

More detail on the research methodology and findings, as well as recommendations related to Title 24 enhancements, further research tasks, and market engagement can be found in the final report.

FAQS

Do heat pump water heaters need ventilation?

MOREYes, heat pump water heaters (HPWHs) can require ventilation, and doing so is often essential for optimal performance. Proper ventilation of the space containing the HPWH ensures the unit has access to adequate thermal energy from the surrounding air. Without proper ventilation, HPWHs may rely on electric resistance backup mode, reducing efficiency and increasing energy use.

Do you need to duct heat pump water heater exhaust?

MOREDucting HPWH exhaust is not always required, but it can improve HPWH performance depending on the installation space and climate zone. Lab testing has shown that dual-ducted installations, where intake and exhaust air are routed from outside the installation space, can help maintain air temperature and efficiency, especially in confined or unconditioned spaces.

How much air does a heat pump water heater need?

MOREHeat pump water heaters require a sufficient supply of ambient air to operate efficiently. While exact requirements vary by model, poor ventilation can lead to lower performance and more frequent use of backup electric resistance heating. Ensuring airflow through proper ventilation or ducting is a critical best practice, particularly in small or enclosed spaces.

What are the downsides of heat pump water heaters?

MOREA common downside is lower-than-expected efficiency when installed in poorly ventilated spaces, such as small closets. Without adequate airflow, the HPWH may switch to their less efficient electric resistance mode. This reduces energy savings and results in higher utility bills and unnecessary strain on the electrical grid.

If you are interested in learning more about heat pump water heater ventilation and other best practices, we’d love to speak with you. Contact us today!

Share this Blog